Oi !!! I’m the coffee nerd here ! Get off my lawn !

Pssh that’s not for making coffee. That looks more like a Soylent Green food unit.

Just don’t ask where the tasty pork treats come from.

B:

oh, I just stepped off the sidewalk a bit. Please take over and splain the machine to us, seeming as how Justin won’t. Will it brew an Americano?

T:

"tasty pork treats"

That is what was in the box!

@Terrence Theory of operation is fairly simple.

- Beans are placed in the hopper

- Beans are heated and screwed in the barrel to around 230 deg C depending on blend.

- 2 piece cup holder is closed together and clamped

- Liquid bean juice is injected into the cup

- Allow to cool slightly

- Cup holder is opened to allow freshly minted product to drop out

- Rinse and repeat

The machine can inject up to 250g of bean juice and has a maximum clamping pressure of 120 tons.

For the Venti Latte that this machine is being purchased for it is going to make them every 4 seconds.

Traditionally all the mechanics are driven by oil hydraulics but this machine being fully electric replaces the hydraulics with servos which are more efficient and alot cleaner when things go pear shaped.

When i say servos they are fairly grunty - the injector servo is rated at 42kw

Crystal?

It was inevitable being around all those computers you were destined to catch a virus

Yes, I knew it.

So the box had beans in it!

So what are you guys making with the injection molder?

A few million flower pots annually for the plant nurseries will be it’s main job.

Hmmm would be fun to do!

But how would you keep them all in lock-step?

I mean if the Master is doing the IO and the Slaves skip over that, would they not go out of sync with the master and then start running code before the master go there?

This would start to get pretty complicated to implement any sort of Kernel level Instruction lock-step.

How about even going simpler, and have all Micro’s running the exact same software (Apart from the one doing the fail over monitoring) and emitting IO, but Writes are MUX’ed away.

So only the Master actually does any Writing on IO.

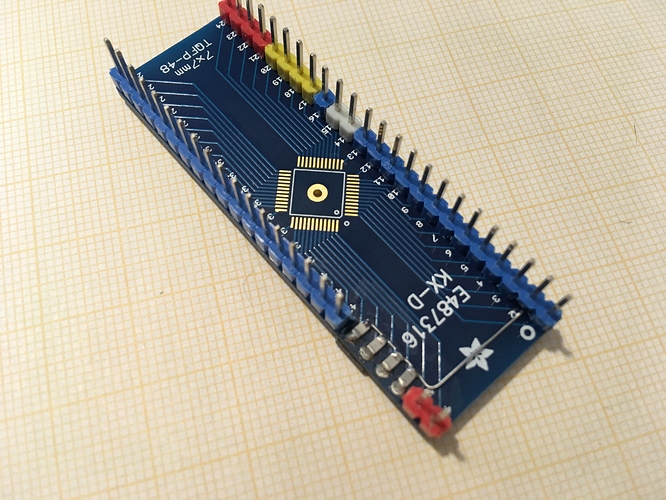

Looks good for quick testing. You really should consider putting the crystal close to the device and use caps with it. You should also put decoupling caps as close as possible to the power pins. I’ve seen to many issues when you miss those off the boards. Otherwise, this looks good.

And back to the subject at hand Justin…

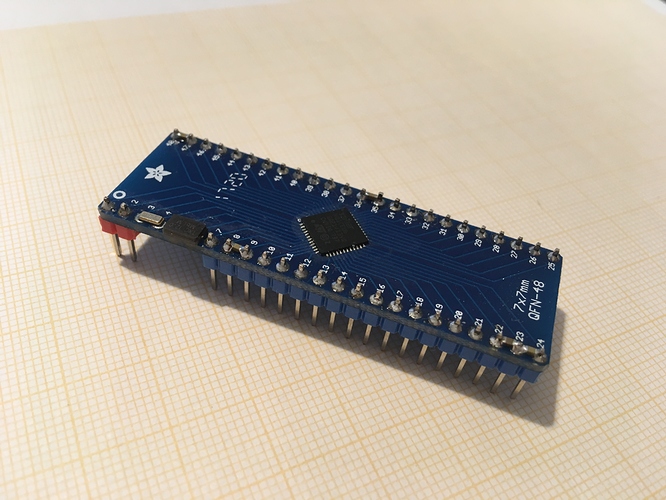

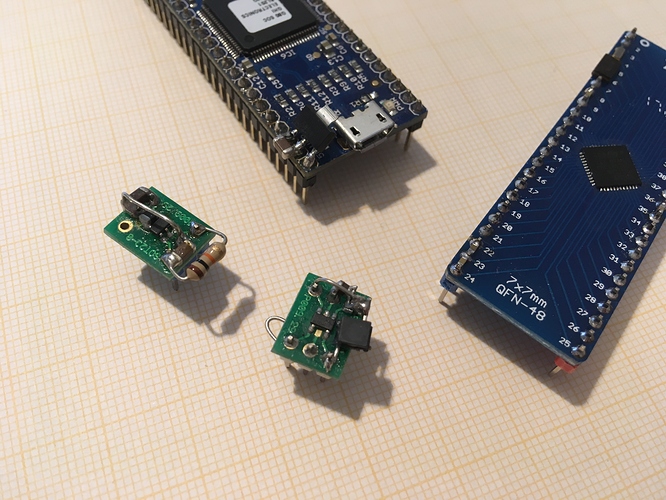

Look what the dogsled dropped off this week! Would have been faster to drop it in a wine bottle and let nature deliver to the the west coast!

Thanks Justin

John

It did make it to Toronto too !

@jscmanson @Designer Glad they both finally arrived, after being rung up by NZ Post about the slow delivery the helpdesk dude said do a quick Google about Royal Mail - seems your postman is taking up to 6 months for small packets!!!

Seems it is the huge influx of small packages from China that the machines cant sort automatically and they all need hand sorting

Think yourself lucky with 6 months. A package I ordered from the UK on the 16th Mar 2016 eventually arrived on the 20th July 2017. The replacement arrived 1 month after I complained about the first shipment after waiting 2 months. I had to pay the premium shipping on the replacement too, to make sure it would arrive this time.

That’s because of traffic: to avoid traffic jam, a lot of packages do a little detour around the moon. You have chance: they don’t go to mars !

I just added some decoupling-and loading-caps  …

…

Somehow I like it to solder SMD-things to places, they weren‘t intend to be  …

…

Hello everyone, any news on this ???

You mean the Electron?

Hmmm Ok Im confuded!!

My Electron was on a older version of firmware… Cant remember what.

I opened VS2017 and deployed a new basic blinking LED app to it. Ran fine.

Went to upgrade to what I thought might be v12, but

Installed the latest firmware v11 http://www.ingenuitymicro.com/downloads/

Ran DfuEeDemo to upload firm ware.

Can see CLR load in TinyCLR Config, and works in and out of Boot Loader mode.

(TinyCLR Config is saying its connecting to FEZCLR device and Core Version is 0.12.0.0 & Device Version 0.12.0.0 ??? How!!!

Installed v11 of VIX in VS2017 (I think I made the mistake and downloaded v12 first (not sure if this was problem)

Created a new TinyCLR project try and deploy and now just get

Found debugger!

Create TS.

Loading Deployment Assemblies.

Attaching deployed file.

Assembly: mscorlib (0.11.0.0)

Error: the reference mscorlib cannot be used with this version of the firmware.

Firmware checksum 0x47604AAF does not match the assembly checksum 0xEE71BD9C.

Resolving.

The debugging target runtime is loading the application assemblies and starting execution.

Ready.Cannot find any entrypoint!

Done.

Waiting for debug commands…

The program ‘[3] TinyCLR application: Managed’ has exited with code 0 (0x0).

electron source exist there (version 0.12.0)

just you need to compile it

install GCC ARM 7.2.1 (as default Next → Next until it was finished)

download source

download CMIS and put on CMIS folder (inside source folder)

download CORE and put on CORE folder (inside source folder)

and build firmware with command build Electron11 (i belive number 11 come from v1.1) v0.12.0

this port done from @Bauland