For the din-rail cases, Wifi a/b/n and BT LE will likely be built into the main compute module. All other radios (Cellular, LoRa, RF Pipe, etc) will be offered as snap-on modules. Of course for the bare board models that Justin is working on, pretty much everything gets connected as a Gadgeteer cable, a socket, or fly-wiring.

@ Justin - What does Tron have to do with anything?

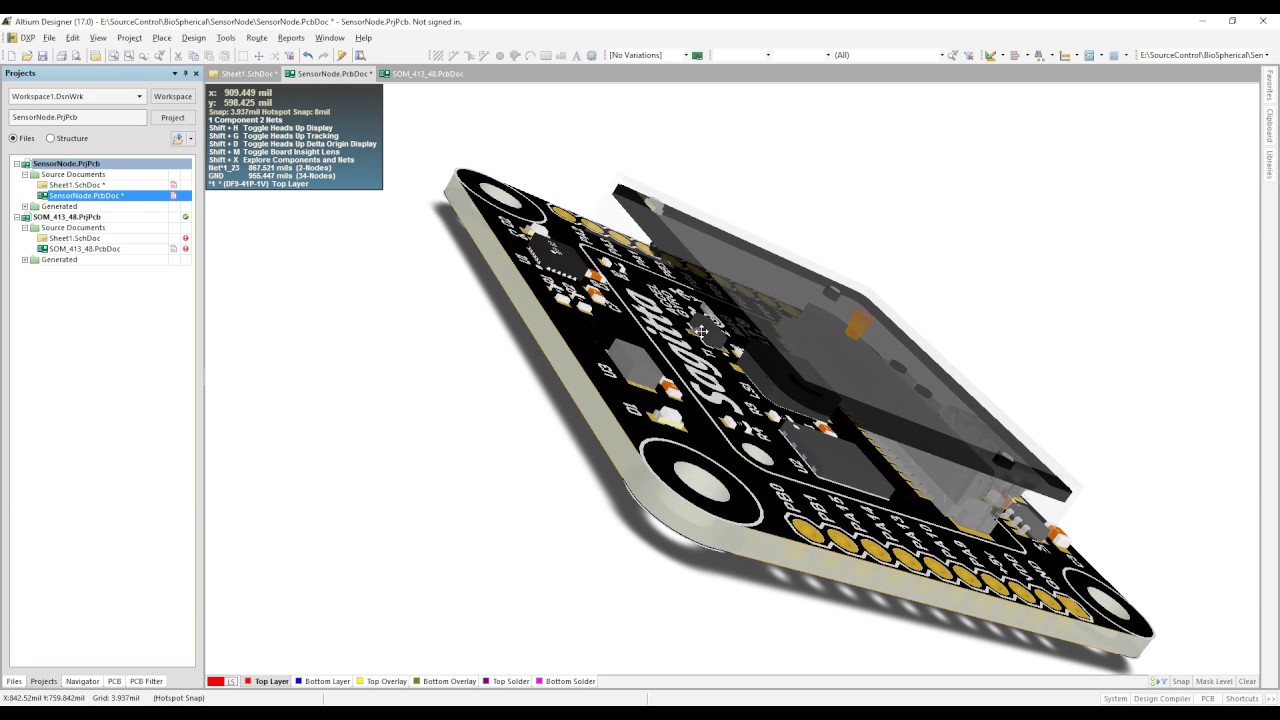

Hummmmm: I think I like it. BioSensor… yeah.

Mmmmmmm - CAD porn. But just like all porn, never as good as the real thing.

(can I say that here?)

Looks a little flimsy for “industrial” :think:

And just as frustrating as it doesn’t get the real thing here any faster.

There’s a lot more pieces to the puzzle yet ![]()

The first iteration is more for firmware development and some early adopters. It’s more prototype-like and not necessarily for deployment. The din-rail and extrusion cases will be the ready-to-field models.

The first iteration is more for firmware development and some early adopters. It’s more prototype-like and not necessarily for deployment. The din-rail and extrusion cases will be the ready-to-field models.

Why waste time on these and not just jump to the DIN rail versions? DIN rail seems it would be just as good for prototyping considering most prototypes tend to end up being the first production version.

Well, no point in polishing the tires on the car before the engine is running, and enclosures really are just polish on a working design.

EDIT: It is faster to do boards without worrying about physical constraints, so I can get some firmware done while Justin does some more refined designs.

And the pieces to the puzzle are on my desk…

@ mcalsyn - Actually, given that some enclosures provide rf shielding, the system should really be tested inside the enclosure as well. I think the stickers on the enclosure would be like the polish on the tires.

Totally understand, and you are correct - but my task is firmware, and with bare boards, I can get started quicker than waiting for enclosure/RF/waterproofing/etc to be solved, which in itself won’t change the firmware in any meaningful way.

@ mcalsyn - I used to think so also. Then I started trying to communicate with stepper motor drivers 14 feet away. Learning to do this required changing the software that handles communication to the drivers. It’s because of this, that I’ve learned that there is no substitute for testing in the production environment; enclosures and all.

@ Mr. John Smith - Totally agree with you on testing in production environs, I’m just saying that it’s not the first step because there’s a huge amount of work before me that I can get on with independent of environment.

Totally understand, and you are correct - but my task is firmware, and with bare boards, I can get started quicker than waiting for enclosure/RF/waterproofing/etc to be solved, which in itself won’t change the firmware in any meaningful way.

That makes sense for supplying you with something to develop on for v0.1 but is the goal for Sagitta to eventually sell both DIN modules and Gadgeteer-like modules? My point was that the DIN modules seem simple enough to prototype with that I wouldn’t bother with planning to sell (and support) the non-DIN version.

Ah - I see what you were getting at. Yes, the snap-together din-rail modules are super simple to work with, however, that comes at a cost. Those cases are expensive and so is the interface glue we have to put into each one (the CAN transceiver, connectors, etc).

If you have the resources, yes, they’ll be great, but I think the bare boards will have their niche due to the better price points.

We are also looking into ways to allow those bare boards to slide into an Al-extrusion casing system so that you can easily field the projects that you build up from bare boards. I am trying to work it out so that the casing system would include end caps and penetrations that are IP65’ish. Basically, you would select an extrusion case of the proper thickness (for the number of boards) and then slide boards into slots where they interconnect either with S-Connect on the back edge or Gadgeteer cables between the boards. The end caps be available with a variety of pre-cut penetrations (and seals) for cables, and I have even found some side panels that allow for membrane keypads and sealed display windows.

There’s a discussion going on as to which would be more desirable to roll out first : the extrusion cases, or din rail. Feel free to express your preference here or in PM.

We are also looking into ways to allow those bare boards to slide into an Al-extrusion casing system so that you can easily field the projects that you build up from bare boards. I am trying to work it out so that the casing system would include end caps and penetrations that are IP65’ish. Basically, you would select an extrusion case of the proper thickness (for the number of boards) and then slide boards into slots where they interconnect either with S-Connect on the back edge or Gadgeteer cables between the boards. The end caps be available with a variety of pre-cut penetrations (and seals) for cables, and I have even found some side panels that allow for membrane keypads and sealed display windows.

I’m having a little difficulty visualizing this. Probably has to do with the headache I’ve had for the past 5 days… If the reason for the non-DIN version is to keep costs down then maybe the boards could be designed such that its easy for developers to 3D print your own enclosures instead of you worrying with extrusions? You could just provide the design files for those that want to go that route.

My opinion may change as I learn more about how this works but my thought right now is that this DIN approach is different/unique than any other NETMF (assuming its NETMF…) approach I’ve seen and I’d rather see you focus on getting that out first. For my personal shop project, I would like to build it as a bit of an IIoT lab experiment using an “industrial” approach and not just a bunch of hacked together Arduinos, etc.