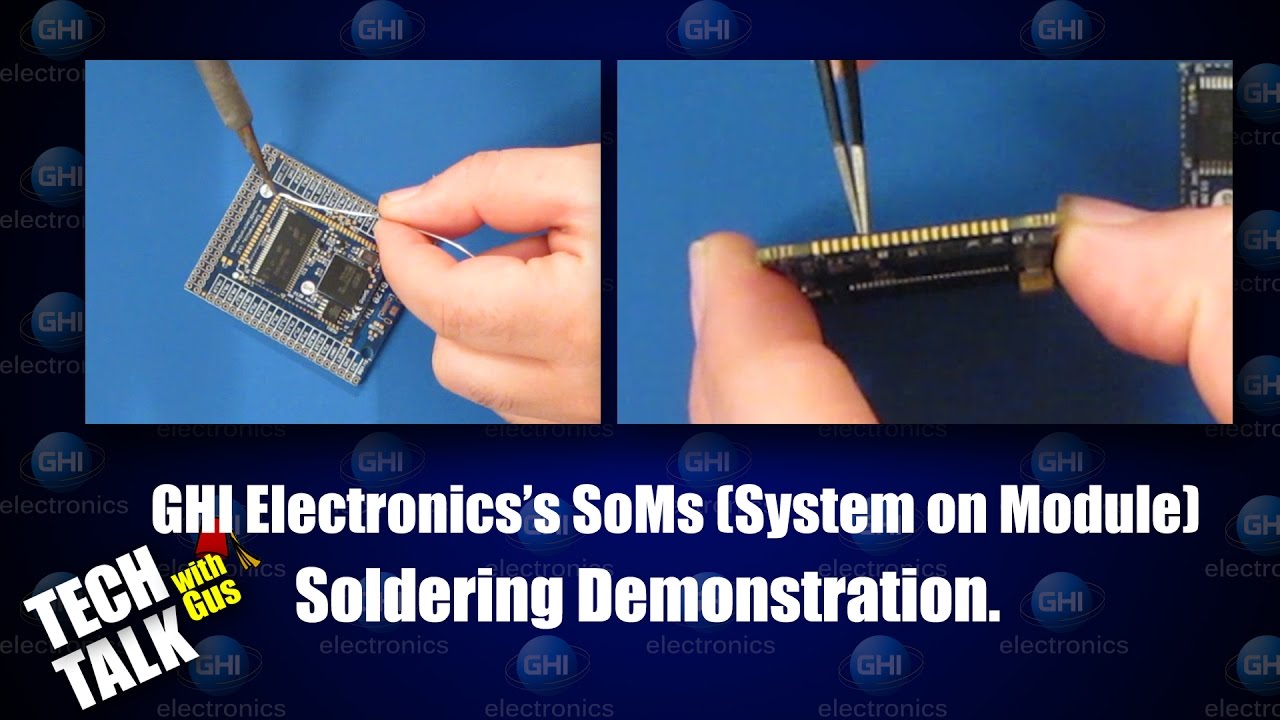

In this episode, Gus talks about GHI Electronics’ SoMs(System on Modules), and demonstrates how to solder them to your own custom designs.

Ah, a Gus soldering video, it’s been a while since we saw one of those !

I actually seeing Gus doing that for the first time. But I’m kinda new… ![]()

Another good one!

Gus, I’m planning to come up and pay another visit in January. We should do an episode together? I’m currently building an IoT catapult. Maybe we could NETMF-ify or Octavo-ify it in some way?

@ ianlee74 - TinyCLR-ify and I am ready.

@ Gus - Thanks for doing these Gus. You have taught me some pretty exciting stuff so far. The variety is good. Please keep them coming.

@ Bill_Wyo - you are very welcome. I am available for special requests as well

Always have a chuckle when American’s say the word soldering or solder, as the L becomes silent. In the UK we pronounce it “sowldering” and the W is to indicate that it sounds more like sow than saw.

Another way to solder them that is much faster is to do as Gus does with the 2 corners and then I apply tacky flux to the pins and then use a large tip with a ideally a concave face but a flat face one will do the job too. You then just flood solder along the edges on one continuous run. The flux helps to make sure the solder flows into the castellated pins. A quick spray with flux cleaner and you have a perfect soldered SOM. I used to do as Gus did but when hand soldering 10 boards it takes too long.

PS… Have to add what cyberh0me said that focusing could be better

Where’s the tip jar?

I remember when Gus made a soldering video centered around replacing the chip on the Fez Domi. This brings back memories.

Since the castelated pins are actually half holes, then would it be possible to use some sort of standard pin headers (either through hole or SMD) such that the module is removable?

@ Mr. John Smith - you could solder pins on the side but I doubt you will have good results.

Mechanically not very strong.

A good hot air rework station gets the G120 off the board quite easily without damage to the main board.

I can attest to this fact as I had to do it about an hour ago due to my own stupidity! :wall:

@ Dave McLaughlin - So I definitely need a good Hakko hot air reflow station… :wall:

Is this one of yours?

If you do a lot of SMD work then yes, it will allow you to repair boards much more easily without damage.

I just removed a faulty ESP12 from a board and fitted a new one and the board is back and working. Took about 1 minute or so heat it up and remove it. No damage to the board this way.

I wish. That one is sexy. It’s definitely inspiring. Especially the unicorn decorations ![]()